Jewelry as a product is synonymous with sustainability because of its durability and longevity. Precious metals are used to make fine and semi-fine jewelry that lasts for a lifetime.

We usually treasure jewelry within the family and passed it on to the next generation. And, even if it becomes out of fashion, we can recycle the metal and gemstones to craft new pieces.

However, the manufacturing of jewelry has several damaging effects on the environment. The mining of metals, gemstones and diamonds has led to erosion, loss of biodiversity and contamination of groundwater.

Several mining units, gemstone cutting and jewelry manufacturing companies operate in developing countries. And, they employ workers on meagre wages with near-hostile working conditions.

The jewelry industry has traditionally been operating on these principles but there are several companies that are promoting and advocating sustainable manufacturing practices.

Customers and suppliers are increasingly becoming conscious to choose manufacturers who are ethical and environmentally responsible.

There are several steps to achieve sustainability within jewelry industry. One of the first and most important phases in the jewelry supply chain is to incorporate traceability. It allows for the strengthening of supply chains and, as a result, the production of trustworthy products.

Let’s understand what exactly is Traceability?

Traceability is an approach for increasing accountability and transparency in the supply chain of a product. i.e. knowing how every material used in manufacturing came from.

“Being responsible and transparent for every process of jewelry manufacturing.”

So, how a jewelry manufacturer can achieve ‘Traceability’?

Blockchain is a technology-based system that traces materials from their inception through their final processing stage. Blockchain is only as useful as the verification of the information that is entered. If anyone tampers the data, the entire concept of traceability within the supply chain will be severely affected. It requires a substantial investment in the infrastructure and technology, thus, making it quite laborious to implement on a wide scale.

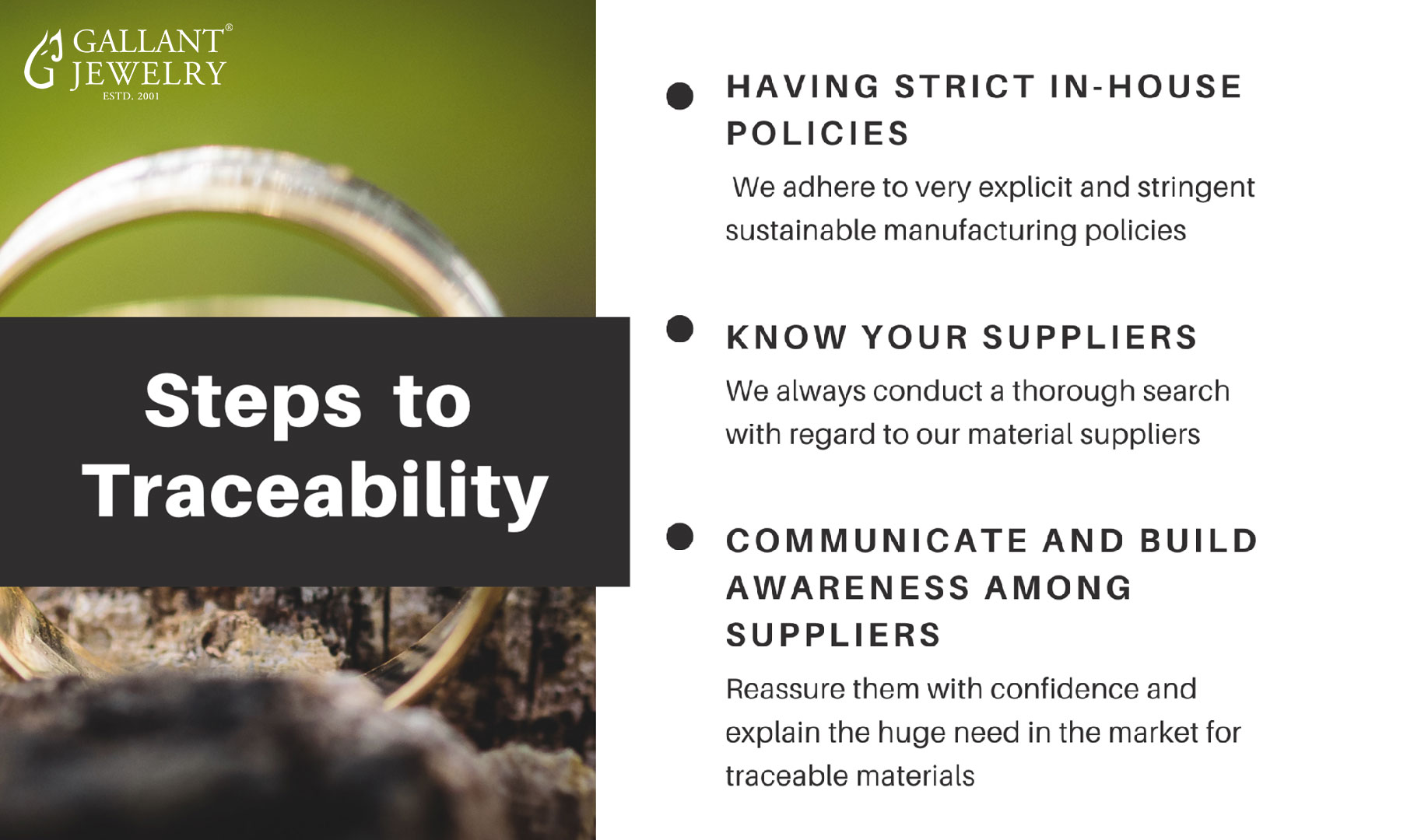

So, what can an organisation do to achieve sustainability without making a massive dent in its budget? Here are a few steps that Gallant Jewelry has taken to achieve traceability within jewelry manufacturing:

1. Having strict in-house policies: For all of our production processes, we have established very explicit and stringent sustainable manufacturing policies, which we strictly adhere to.

2. Know Your Suppliers: We always conduct a thorough search with regard to our material suppliers. And always request them to provide us with the proof of origin of their materials.

3. Communicate and build awareness among suppliers: Because we have long and trustworthy connections with our vendors, it sometimes becomes difficult to question the authenticity of the products' origins. However, we reassure them of our faith in our business connections by explaining the huge need for traceable materials and the promising future of sustainable practices.

Complete traceability in jewellery manufacturing is still a long way ahead, but any jewelry manufacturer can adopt these small steps. It will inevitably lead to enormous benefits in the long run, not just for businesses but for the entire globe.